What is Electrical Insulation System?

A total systematic evaluation is necessary for

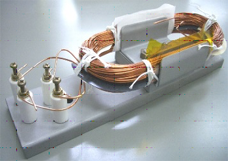

polymeric materials including magnet wire

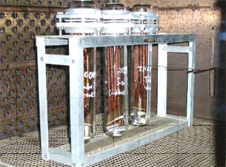

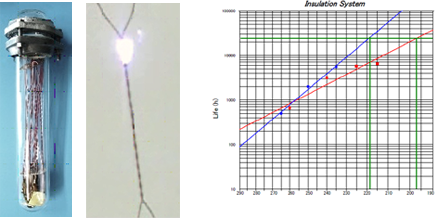

The test process can be greatly reduced if it is possible to use the already certified insulation system which is called a Reference System, and a lot of Reference Systems are registered with material manufacturers. Major components for insulation need to be selected from the registered systems, but minor components can be added by conducting sealed-tube tests that can be completed in a shorter period of time. The component can pass the test if its dielectric breakdown voltage does not reduce to less than half of the dielectric breakdown voltage of the reference system after conducting dielectric breakdown test under the condition of 336 hours aging by 25C higher temperature than the desired thermal index.

List of Standards

| Test Name | Standard Number | Standard Name | Object |

|---|---|---|---|

| Dielectric Breakdown Test |

UL1446 | Systems of Insulating Materials | Insulation System EIS |

| IEC60085 | Electrical insulation – Thermal evaluation and designation | Insulation System EIS |

Contact Inforamtion

PIC: Makoto Horimizu (Mr.)

TEL: +81-551-42-5061