We can arrange sample molding and testing in short turnaround time.

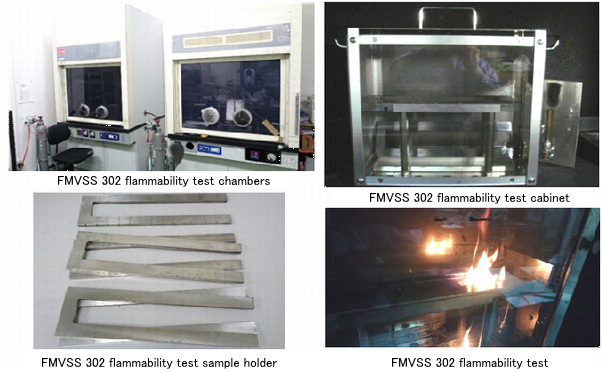

FMVSS 302 Flammability Test for Motor Vehicle Interiors evaluates the burn resistance of materials in the occupant compartments of motor vehicles, including passenger cars, multipurpose passenger vehicles, trucks, and buses. In order to respond to the growing need for FMVSS 302 Flammability Tests, we have established a system that enables us to assist you from a sample molding process to complete testing very quickly. If you simply provide us with plastic pellets, you do not need to do anything.

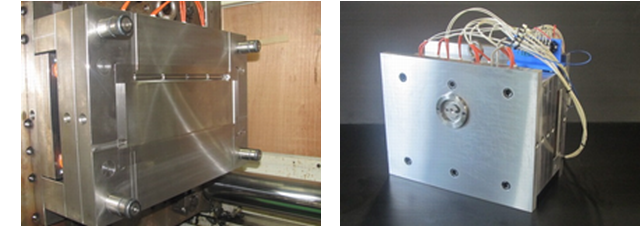

Photo of Molding Die

※Sample we can mold: Thermoplastic Resin, Size: 102 mm × 356 mm, Thickness: Any thickness between 1.0 to 3.0 mm

220-ton Electromotive Injection Molding Machine |

Compared to the hydraulic type, the 220-ton electromotive injection molding machine has a much better stability on sample dimensions and variation. |

Strict Management of Test Environment Based on ISO/IEC 17025 Standard.

We have a rigorous management procedure for sample storage and our lab environments.

Controls of sample conditioning and test environments are critical, especially for the automobile industry to obtain accurate data.

For over 40 years, Chemitox has been a leading independent testing laboratory in Japan and currently provides authorized data based on A2LA accredited based on ISO/IEC 17025.

With our knowledge and rich experience in test environment management according to various standards, we can provide accurate evaluation data to our customers.

Sample Storage and Test Environments For Each Standard

| Standard | Applicable Country | Sample Conditioning | Lab Environment |

|---|---|---|---|

| Basic Requirement | - | Being maintained at 23 ±2℃/50 ±5%RH for 24 to 168 hours. | 20 ±5℃ / 50 ±5%RH |

| FMVSS 302 | USA | Being maintained at 21℃/50%RH

for 24 hours (Being maintained at 16 – 26℃/50 – 60%RH for 24 hours or more) |

21℃ / 50%RH (16 – 26℃ / 50 – 60%RH) |

| CMVSS 302 | Canada | ||

| ASTM D5132 | USA | Being maintained at 23 ±2℃/50 ±5%RH for 24 hours or more | 15 – 35℃ / 45 – 75%RH |

| SAE J369 | USA | Being maintained at 23 ±2℃/50 ±5%RH for 24 hours Upon completion of above conditioning, it is possible to maintain a sample in a sealed polyethylene bag for a maximum of 1 hour before the test. |

15 – 35℃ / 45 – 75%RH |

| ISO 3795 | Europe | Being maintained at 23 ±2℃/50 ±5%RH for 24 hours to 7 days | 23 ±2℃ / 50 ±5%RH |

| GB8410 | China | Being maintained at 23 ±2℃/50 ±5%RH for 24 hours to 7 days | No Regulations |

| GMW3232 | ― | As Received: Being maintained at 22 ±3℃/50 ±5%RH for 24 hours or more After aging: After Being conditioned under 40 ±3℃/93 ±5%RH for 48 ±1 hours, condition again at 90 ±3℃ for 168 hours |

22 ±3℃ / 50 ±5%RH |

Required Sample Size and Quantity of Each Standard

| Standard | Sample Size | Quantity | Remarks |

|---|---|---|---|

| FMVSS 302 | 102 mm × 356 mm (If it is not possible to fit with the above dimension, use maximum size as possible) |

No Regulations | United States Department of Transportation procedure has no regulation on quantity, but data sheet enclosed on the procedure specifies more than 4 samples (MD/TD: minimum 2 for each). |

| CMVSS 302 | No Regulations | - | |

| ASTM D5132 | 100 ±5mm × 300 mm minimum | 5 or more samples | - |

| SAE J369 | (95 –102 mm) × (300 – 356 mm) | 5 or more samples | - |

| ISO 3795 | 100 mm × 356 mm | 5 or more samples | |

| Actual product width (in case of 3 – 60 mm) × 356 mm | 5 or more samples | The minimum value in case it is not possible to fit with required dimension. | |

| (60 – 100mm) ×138 mm minimum | 5 or more samples | ||

| (Less than 60 mm) × less than 356 mm | - | Impossible to conduct test | |

| Less than (60 – 100 mm) × 138 mm | - | Impossible to conduct test | |

| GB8410 | 100 mm × 356 mm If the size is smaller than the above: The minimum length of 356 mm is required for the width of 3 – 60 mm. In case the width is larger than 60 mm: The minimum length of 138 mm is required. If the size is less than the above then it is impossible to conduct the test. |

5 or more samples | Conduct test individually on both directions if the burning rate differs for each side. |

Contact Information

PIC: Hitoshi Watanabe (Mr.)

Phone: +81-551-42-5061